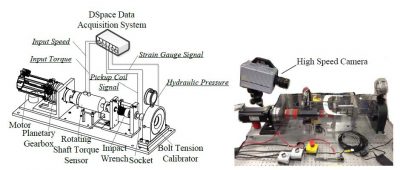

Machinery dynamics is one class of problems in the general area of dynamic systems. A recent case that we study is electric impact wrench, an important tool used in manufacturing and maintenance services. It has complex mechanism and its operation involves dynamic events occurring at vastly different time scales, which poses challenges for efficient and accurate modeling to facilitate design optimization and control. This investigation establishes a first-principle-based, system-level model of a representative impact wrench. The model explicitly incorporates the dynamic flexibility of gear transmission, spindle shaft, and impacting components into the kinematic relations that connect them together. The nonlinear impact and contact events, coupled with the rotational and translational motions of all components, are explicitly analyzed, and systematic parametric identification is performed based on a multi-objective optimization approach. The model prediction is correlated with experimental studies. The test rig configuration is show in the figure below.

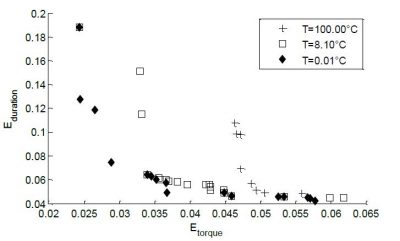

A series of techniques are adopted in modeling and system identification. Archived Multi-Objective Simulated Annealing (AMOSA) is employed in parametric identification. The optimization results (Pareto front) are illustrated in Figure 2, where objective function values under different temperatures throughout the simulated annealing-based computation are plotted.

A side-by-side animation/video comparison between the model prediction and the actual operation is demonstrated in the video, which shows precise matching.