The dynamic responses of a mechanical structure contain information that can be used to elucidate its health condition. The advent of various transducer materials/devices and the rapid progress in microelectronics in recent years have resulted in the exploration of integrating sensory system to a structure to perform continuous and online monitoring of its health, known as Structural Health Monitoring (SHM). In order to detect and identify fault in a mechanical structure, the wavelength of the dynamic response measurement must be smaller than the already extremely small characteristic length of the structural fault. Meanwhile, the finite element analysis (FEA), a versatile tool for structural modeling and analysis, can accurately predict the dynamic response, only if the meshed element size is significantly smaller than the wavelength involved. In other words, to facilitate damage identification, an inverse problem with enormously high dimension has to be analyzed in high-frequency detection, which not only is computationally costly, but also, may yield a severely under-determined problem because the number of unknowns (i.e., the status of each finite element) may far exceed the amount of input information (e.g., response magnitude changes at given frequency points). This difficulty is further compounded by the inevitable modeling error and measurement noise.

As new sensing modalities and sensors are synthesized at DSCL, concurrently we develop highly accurate and robust damage identification algorithms. Our recent exploration is based on data-driven technique to overcome the drawbacks and limitations of approaches purely based on first-principle models. In the case of piezoelectric impedance-based damage identification, we develop the followig method:

- Step 1: We formulate the sensitivity relation between the impedance measurement vector and the damage index vector based on first-principle finite element analysis;

- Step 2: Using the measument data and the sensitivity relation, we perform pre-screening of the damage index vector and rank the likelihoods of fault locations with estimated fault severity levels;

- Step 3: For fault locations/severity levels with high likelihoods, a Bayesian inference approach is incorporated to pinpoint the fault location and severity with high computational efficiency.

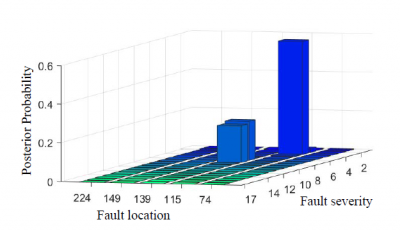

It is worth pointing out that, without the data-driven pre-screening step, the Bayesian inference alone cannot be realistically employed, because of the prohibitive computational cost involved in analyzing hundreds of segments each having thousands of possible severity levels. Meanwhile, the pre-screening step is approximate in nature and thus employing it alone cannot pinpoint the fault occurrence. The combination of these two can be effective in solving the fault identification problem. Shown in Figure 1 is one set of result illustration. The fault location and severity are identified in the probabilistic sense. Only 10 location candidates each having 11 severity candidates are needed in Bayesian inference.

Figure 1. Posterior probability distribution from Bayesian inference after data-driven pre-screening.